Iron Market

Pellet Feed is produced at our Minas el Romeral, Pellet Plant and Magnetite Plant facilities. Ore

The pellet feed is a low-sized marketable iron ore, which must be agglomerated in pellet form for use as an input in the blast furnaces.

blast furnaces. It is regularly used to charge the agglomeration process and pellet production.

Law:

66%, 67%, 68% Fe.

Dimensions:

Less than 44 microns (1,000 microns = 1 millimeter) 75% Min.

The iron ore pellets are produced in our Pellets Plant facilities.

Pellet Plant, this product is classified into:

–

Basic or Autofunding Pellets

Iron ore fines agglomerated in the form of nodules. The term self-fluxing means that they are manufactured with a special alkali additive such as limestone or dolomite. It is used in direct charging to blast furnaces for pig iron production.

Used in direct charging to blast furnaces for pig iron production.

Law:

65% Fe.

Dimensions:

9 to 16 mm. 85% Min.

–

DIRECT REDUCTION PELLET

Agglomerated iron ore in pellet form, for use in direct reduction processes, which require lower impurities and higher iron content than blast furnace. It is used in steelmaking processes direct reduction method, which deliver sponge iron as a product.

Law:

66.4% Faith

Dimensions:

9.5 to 15.9 mm. 89% Min.

–

PELLET CHIP

It is the pellet that has been broken in its production process.

It is regularly used in sintering process, in coal washing, formation of muds used in oil well drilling.

Law:

65% Fe. 66.4% Fe

Dimensions:

9 to 16 mm. 85% Min. 9.5 to 15.9 mm. 89% Min.

The Granza (granulated iron ore) is produced at our Minas el Romeral facilities, which have their own ore crushing plants.

It is the traditional product of iron ore mines and is generally subjected to a beneficiation process to separate it from the gangue, thus increasing its iron grade. It is used in direct charge for pig iron production.

Law:

61% Faith

Dimensions:

10 to 30 mm.

Fino is iron ore produced at our Minas el Romeral and Pellet Plant facilities. It is marketable iron ore that must generally be sinter agglomerated to subsequently feed a blast furnace. It is used in the sintering process to produce nodules as a direct charge to the blast furnace and for pig iron production.

Law:

62% Fe.

Dimensions:

5% max. over 10 mm 10 mm + 6.3mm 20% max. | 150 micron 20% max.

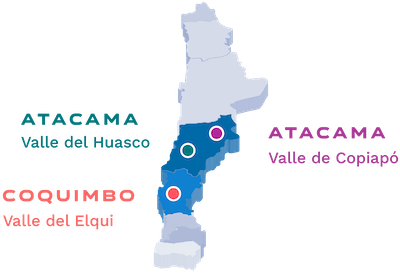

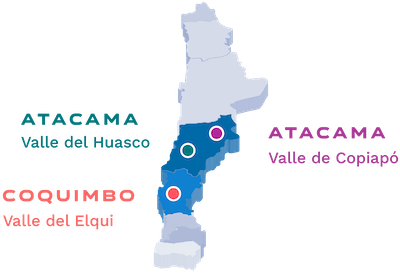

Copiapó Valley

Copiapó Valley

Cerro Negro Norte Mine

Cerro Negro Norte Mine

Magnetite Plant

Magnetite Plant

Puerto Punta Totoralillo

Puerto Punta Totoralillo

Huasco Valley

Huasco Valley

Los Colorados Mine

Los Colorados Mine

Pellets Plant

Pellets Plant

Puerto Guacolda II

Puerto Guacolda II

Elqui Valley

Elqui Valley