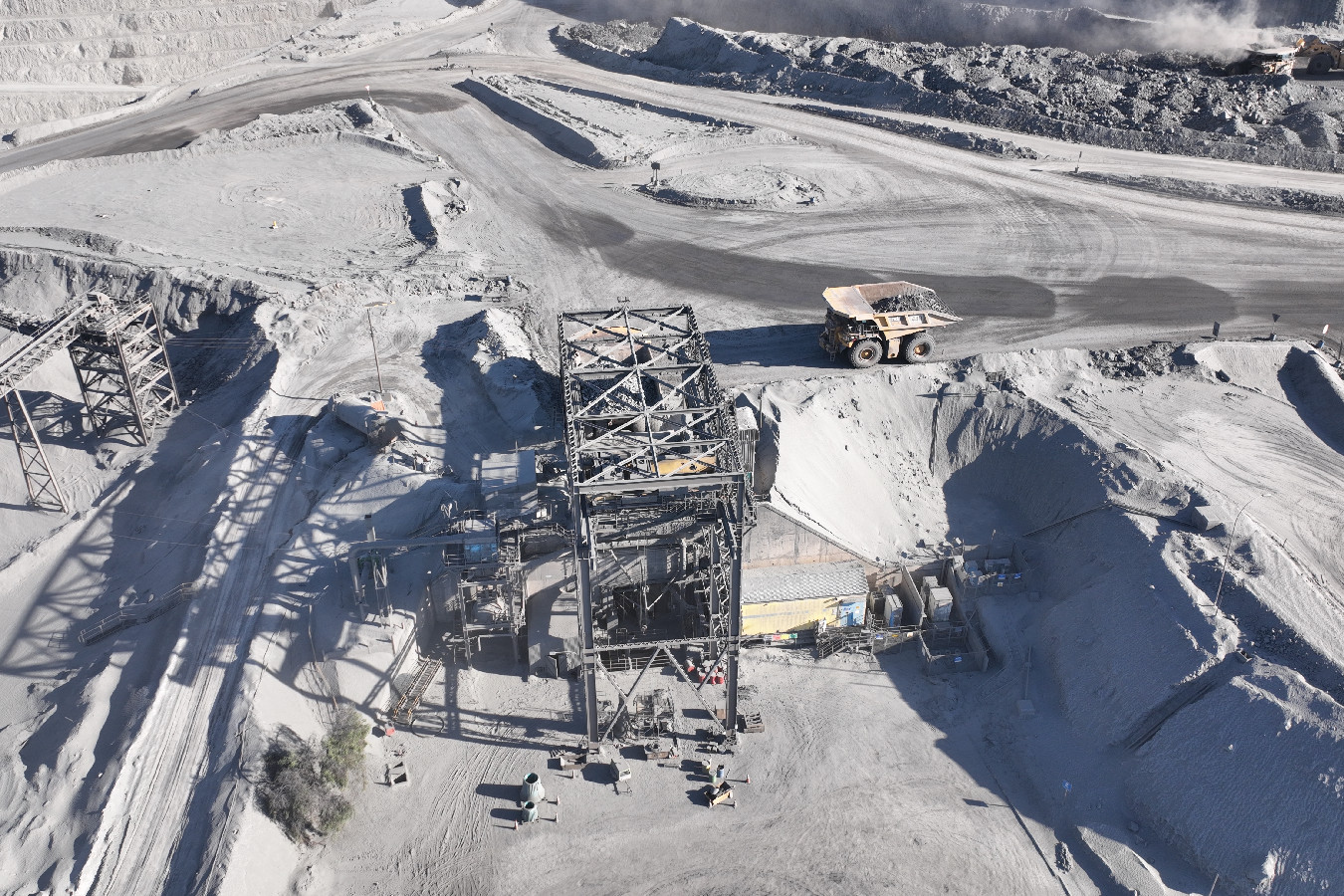

LOS COLORADOS MINE

cmp's youngest deposit

LOCATION

Los Colorados Mine is located approximately 30 kilometers northwest of Vallenar, in the commune of Huasco. Its main objective is to supply iron pre-concentrate and Sinter Feed to the Pellet Plant, also located in Huasco.

It has a total annual throughput of 84 million tons, of which 10,400,000 tons correspond to iron ore. It is an open-pit mine with 15-meter-high benches and is currently in its sixth phase of exploitation.

DRILLING AND BLASTING

It has five primary drilling rigs for drilling in 10 5/8′′ diameter and a pre-cutting drilling service in 6′′ diameter. Blasting is performed by an external company.

LOADING AND TRANSPORTATION

Loading is carried out with two electric rope shovels, two hydraulic shovels and three front-end loaders.

Transportation is carried out with eight trucks of 200 short tons capacity and 15 trucks of 240 cgt capacity.

DEVELOPMENT

There are five crawler tractors, four wheeled tractors, two motor graders, three irrigation trucks, one for water supply to the drilling rigs, and one for water supply to the drilling rigs.

Processing plant

It reaches a feed of 10 million 400 thousand tons per year, with a Fe grade of 46.4% to produce 7 million 200 thousand tons of pre-concentrate, which is sent by rail to the Pellet Plant through Ferronor's contracted service.

PRIMARY CRUSHING

The primary crushing area receives ore of a maximum size of 44′′ in a 300-ton capacity bin, which feeds a 54′′x74′′ gyratory crusher in open circuit at a rate of 2,200 tons per hour. The crushed product is deposited in an intermediate stockpile of 30,000 live tons capacity.

SECONDARY CRUSHING AND SCREENING:

The material is extracted from the intermediate stockpile by six electromechanical feeders located in a tunnel under the stockpile, which is then fed into a trough. The oversize is reduced in an open circuit with a standard 7′ secondary crusher.

ROLLER PRESS

In a third stage, the ore is subjected to size reduction in a closed circuit by means of a high pressure roller press; it is then classified in five conventional 8'x 20'' screens.

Magnetic Concentration.

The low size of the screens is limited to a dry concentration system using high speed magnetic drums, arranged in two successive stages. The primary concentration stage consists of twelve drums, as does the secondary concentration.

PRECONCENTRATE PILLAR

The plant's product, called pre-concentrate, is stored in a 140 thousand ton capacity stockpile. From this stockpile, the ore is extracted through 11 vibrating feeders, located in a tunnel under the stockpile and with conveyor belts to a train loading tower, which has two hoppers with a capacity of 220 tons.

It started operating in 2012 and consists of a dry magnetic concentration plant, which allows processing fresh rejects generated by the operation of the Beneficiation Plant. It also processes the rejects stockpiled in the nearby industrial area, from previous periods of operation of the plant, with an average grade of 14.5% magnetic iron.

Copiapó Valley

Copiapó Valley Cerro Negro Norte Mine

Cerro Negro Norte Mine Magnetite Plant

Magnetite Plant Puerto Punta Totoralillo

Puerto Punta Totoralillo Huasco Valley

Huasco Valley Los Colorados Mine

Los Colorados Mine Pellet Plant

Pellet Plant Puerto Guacolda II

Puerto Guacolda II Elqui Valley

Elqui Valley El Romeral Mines

El Romeral Mines Pleito Mine

Pleito Mine Puerto Guayacán

Puerto Guayacán